in chemical formulation and high precision coatings

a worldwide presence (Europe, Asia, North and South America, South Africa)

Specialized in the industrial formulation of inks, the company is the world leader in the manufacture of thermal transfer ribbons. Drawing from its expertise, ARMOR GROUP makes its cutting-edged know-how in chemical formulation available to battery manufacturers.

Over the years, the group has successfully developed an extensive portfolio of conductive particles (graphites, carbon blacks, acetylene blacks, carbon nanotubes, graphenes, etc.) as well as a wide range of binding systems with diverse properties (hydrophilic, hydrophobic…) required by industrial partners.

This work contributes directly to its continuously expanding range of primers, enabling ARMOR GROUP to offer innovative coating solutions to meet the performances required (adhesion, chemical protection, electrical conductivity, etc.).

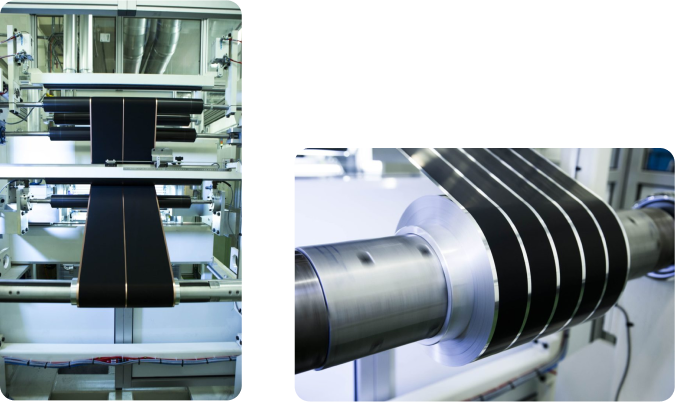

With its expertise in coating ultra-thin layers on thin films (from 4 to 15 µm) and an annual production of over 2 billion linear meters, ARMOR GROUP offers a wide range of coating and printing techniques for large-scale industrial production, such as flexography, rotogravure rollers, slit die, rotary screen printing and coating, etc.

These various technologies enable the use of a wide range of thin substrates such as metal foils (copper, aluminum, titanium, nickel) and plastic films (PET, PP/PE).

With coating speeds ranging from 80 meters to 1000 meters per minute, ARMOR GROUP develops its own processes and places precision at the heart of its operations. ARMOR GROUP ensures coating quality through an in-line control process over the entire film surface, and quality monitoring throughout the production process (thickness, 2D, visual appearance, etc.).

ARMOR GROUP invests 7% of its sales in innovation and employs 120 engineers in R&D, process development and continuous improvement.

Machine learning, automation, robotization, profitability and environmental impact are at the heart of ARMOR GROUP’s industrial processes.

Serving the automotive, pharmaceutical, aerospace and energy industries, ARMOR GROUP is used to meeting customer requirements with high quality standards.

With a presence in over 28 countries, ARMOR GROUP’s local team will support you, while our highly experienced global logistics team ensures that we deliver the right product, to the right place, at the right time.

QSE and ESR are at the heart of our management system. Our quality and logistics organizations are in line with the highest international standards. AFAQ, OEA, Global Compact, ECOVADIS RSE (Gold).

Would you like to set an appointment during one of the exhibitions ?